Finishing By Grinding

To produce high quality boards with maximum speed, the flute profile should be accurately ground, and the surface should be completely smooth. Our unique "Finishing by Grinding" procedure ensures an accurate flute profile as designed with unform coating thickness. The coating surface is also as smooth as a chrome plated surface(Ra is less than 0.2um).

Hardening

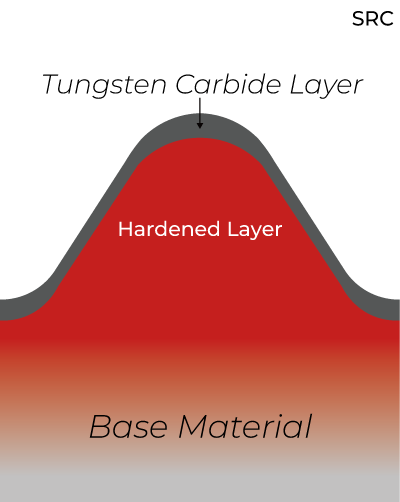

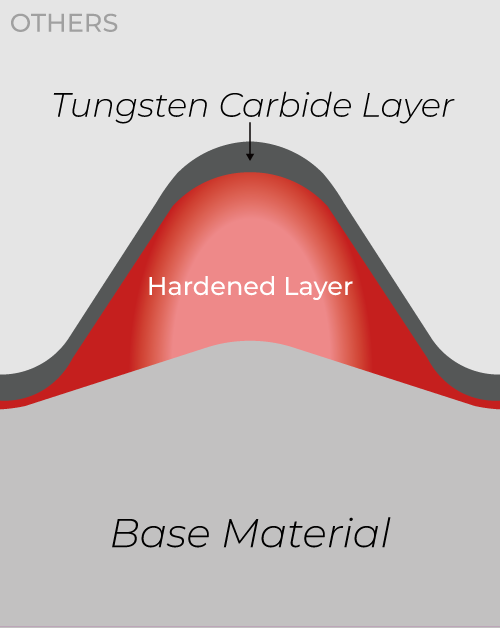

In order to build durable corrugating rolls it is important to increase surface hardness while keeping the roll less brittle. Most common method to increase the hardness of raw material is high frequency induction hardening after flute forming. Although this method is easier and cheaper, it has disadvantages – shallow hardened layer with uneven hardness distribution. Thereby the rolls are brittle.

SRC takes different approach to build more durable rolls. We do low frequency induction hardening for deeper hardened layer with uniform hardness distribution. In addition the raw material is hardened before flute forming to reduce cracks or break-up of flutes.

Quality First

At SRC, every product must meet the highest quality control standards before leaving our facility. Our corrugating rolls are subjected to rigorous testing at specialized test stations designed exclusively for this purpose. The rolls are heated to 180 degrees Celsius using steam, and we evaluate the parallelism and accuracy of the crown. We also perform take-up tests with both lightweight and heavyweight medium paper to ensure optimal performance. Only those rolls that meet our rigorous standards are approved for shipment. This uncompromising commitment to quality ensures that our customers achieve maximum productivity from day one, with any operational issues.

Shortest Delivery

At SRC, we are committed to meeting our customers’ needs in the shortest time possible. All manufacturing processes for our corrugating rolls are carried out in-house, ensuring optimal efficiency and quality control. With a large inventory of cores ready to be ground to any desired flute profile, we can complete new production orders within 40 days. Located in Wisconsin, we can deliver anywhere in the United States within 2-3 days.

ADVANTAGES

Durable

The hardened, but not brittle, layer provides a better base for tungsten carbide coating or chrome plating with excellent wear-resistance. Our patented HVOF spraying process provides a tungsten carbide coating with excellent wear-resistance and great adhesion strength.

Reliable

SRC corrugating rolls ensure trouble-free operations from day one. Specifically, our ‘Finishing by Grinding’ process provides a smooth and uniform coated surface while implementing accurate flute profiles as designed.

Flexible

In addition to conventional flute profiles (U, V, UV), we offer ‘flank relief profile’ and ‘double R profile’ to meet the needs of our customers. Since we are using ‘dressing disk without predetermined profile’, an almost unlimited number of flute profiles can be designed and produced. Our flexibility provides a competitive advantage to our customers.

Economical

Together with intensive R&D and expertise from our considerable experience, SRC can offer our customers the most cost-effective flute profile options while maintaining excellent board quality. In addition, our unique surface hardening technology and sophisticated grinding knowledge enable us 4~5 regrinding opportunities that deliver our customers more cost-reduction benefits.